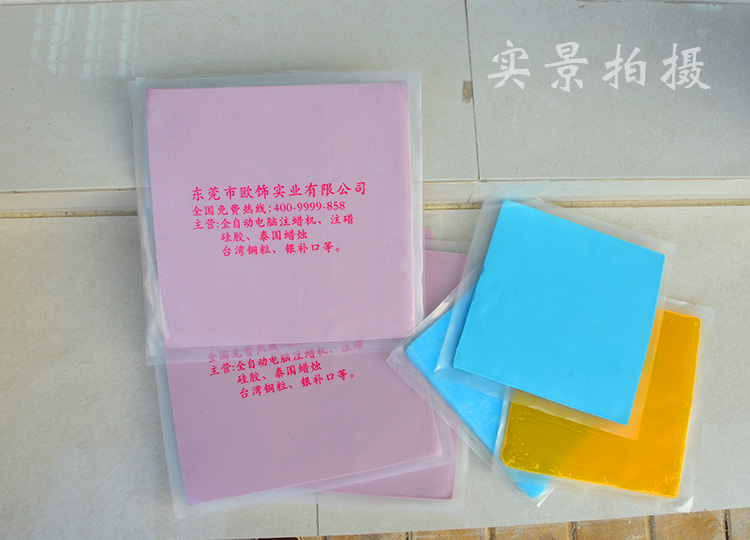

Domestic wax-coated silicone

- Product introduction

First, the die frame and model

For the die frame, please select the aluminum frame with better heat conduction. Please note that the die frame must be kept flat. Do not use the bad die frame. The V-shaped grooved die frame helps the air to drain. It is the best. The die frame style.

The model must be kept clean, so clean the model thoroughly before pressing.

Second, loading rubber

Too much or too little rubber in the filling process is an inappropriate compression molding method. Please confirm the thickness of the molding frame before pressing the mold. The total thickness of the appropriate molding compound is 1-2mm above the thickness of the molding frame. optimal. In order to ensure the integrity of the rubber mold and the complex parts, please cut the appropriate size when filling the rubber, and indeed fill the rubber in small and complex parts.

Place the model in the center of the die frame when filling the glue. The number of films used in the upper and lower layers should be as consistent as possible.

Unclean mold environment and sweat and oil stains on the hands will contaminate the rubber. Unclean rubber will cause the rubber mold to smash. Please use tweezers or other tools to mold.

Third, heating vulcanization

The standard vulcanization temperature is 165 degrees Celsius, based on a 10 mm stamper frame heating for 25 minutes. The die frame must be increased by 2 minutes for each 1 mm vulcanization time. The die frame is preferably no more than 30 mm.

Before adding sulfur, the molding machine must be preheated to a set temperature of 165 °C. When adding sulfur, the model to be vulcanized should be placed in the molding machine and gently pressed for about 1 minute. The mold frame should not exceed 30 mm. optimal.

If the temperature of the molding machine drops more than 30% of the set temperature when starting the molding, and the molding machine fails to rise to 155 °C within 10 minutes, the optimum vulcanization effect will not be achieved. It is recommended to use a larger heating. Power molding machine.

The temperature display on the molding machine is not very accurate. Please use the temperature detector to measure the actual temperature on the molding machine when purchasing the molding machine to achieve the best vulcanization effect.

Fourth, cooling

Use a pair of pliers to remove the heat-resistant cloth before cooling.

Natural cooling and water cooling can achieve the same result. The cooling time can be shortened when using water cooling, and the plastic mold retains plasticity when it is not completely cooled. Do not perform mold opening work.

Fifth, open the mold

A better rubber mold can be obtained by using the mold opening aid. Please keep the sharpness of the mold opener. The poorly cut tool will increase the difficulty of mold opening and the flaw of the mold, and it is easy to produce a model engineer's work accident.

Six, save

The rubber should be kept in a cool place, and the best storage environment temperature is between 15-30 degrees Celsius.

Precautions

The new rubber has the best performance in three months. The unvulcanized rubber will gradually reduce the rubber performance and shorten the service life as the storage temperature increases, and the vulcanization phenomenon generated in the high temperature environment may eventually lead to the scrapping of the rubber. , please use it in turn according to the date of preservation. Usually in a good storage environment, even after one year, you can get the same performance surface as new rubber. At too low a temperature, the rubber will harden temporarily, usually returning to normal temperature to restore the original performance, and too high storage temperature will accelerate the aging of the vulcanized rubber to reduce the service life.

Demolishing

Dongguan Ours Industrial Co., Ltd. is committed to optimizing the jewelry process;

Buying equipment, sending technology, free training, one step in place.

Dongguan Factory Headquarters:

Songshan Lake High-tech Industrial Park, Dongguan City (24-hour service hotline: 400-9999-858)

Dongguan Exhibition Hall:

No. 11 Rongwen Road, Chang'an Town, Dongguan City (Miss Huang: 136-9185-3787)

Shenzhen Office:

Liuyue Zhonghe Shengshi District C, Longgang District, Shenzhen (Miss Li: 188-2583-5713)

Yiwu Office:

Chouzhou North Road, Yiwu City, Zhejiang Province (Miss Li: 188-0256-1183)

Technical guidance: Mr. Zeng (137-2815-5712)

Online store: www.gdours.1688.com

Email: gdours@163.com