Double station waxing machine

- Product introduction

Features:

1. Fully automatic vacuum computer micro-inlaid wax injection machine is the latest achievement of our company's independent research and development after years of hard work. It is a high-tech product with international patents.

2. This product adopts international leading control technology and gas-electric control valve module group. It is the only fully automatic vacuum computer micro-inlaid assembly line with the highest degree of automation, highest production efficiency and highest product quality. The structure is compact, beautiful and has a small footprint.

3. The perfect human-machine integrated design for your peace of mind, labor, money, and save trouble.

1)saving labor 80%: only need manual drafting, and truly achieve automation.

2)Significantly save the plant area: This product occupies no more than 4.5 square meters. Compared with the traditional wax injection machine, it is necessary to reserve enough space for workers to greatly reduce the cost of factory rental.

3) Energy-saving: The first-class automatic control technology ensures that each wax-filling tank can consistently inject wax, not idle, and not waste every second, thus greatly reducing the number of wax tanks and saving energy costs.

4) Green and environmental protection: This product does not produce waste gas, waste water and no noise.

4. The efficiency is 40 times that of the traditional wax injection machine: at least 4 excellent products can be produced per second. The machine is equipped with a cooling system, and the wax mold is immediately subjected to forced cooling after the wax is filled. The mold can be opened when the wax pattern is delivered to the workbench.

5. Product quality increased by more than 98%: the use of infrared scanning bar code recognition memory system, the control system intelligently obtain the relevant data of each wax mold, automatically call the wax injection parameters, thus achieving the traditional product pass rate exceeded 100%, micro-inlay product pass rate Up to 99% quality assurance, especially the micro-inlay products that traditional wax injection machines can't achieve. The company's fully automatic vacuum computer micro-inlaid wax injection machine can be realized, which is the best choice to solve the micro-inlaid technical problems.

6.A wide range of applications: gold, silver, copper, stainless steel, dental, glasses, watches and other jewelry manufacturers and the use of lost wax mold casting process manufacturers of the best choice.

7.Quick and easy operation: According to the shape and size of the product, you can directly input, recall and modify various parameters through the Chinese visual color touch screen operating system, and freely convert any functions such as manual, semi-automatic, linkage, automatic, monotonous, etc. You only need to spend two In three minutes, you can easily control the entire assembly line with a single finger movement and monitor its running status in real time.

8. Each station can be installed with different sizes of molds, to achieve a powerful multi-function.

Introduction to the workflow:

1. Set or call related parameters through the touch screen

2. Place the wax pattern with the barcode attached to the die line

3. The following steps are automatically completed by the device

1) into the assembly line

2) scan the barcode to get the wax mold parameters

3) automatically send the wax mold into the fixture

4) automatically adjust the wax injection parameters according to the barcode parameters

5) start waxing

6) waxing finished, the wax mold automatically returns to the mold line and forced cooling of the wax mold

4. Drafting

5. Excellent products are in place

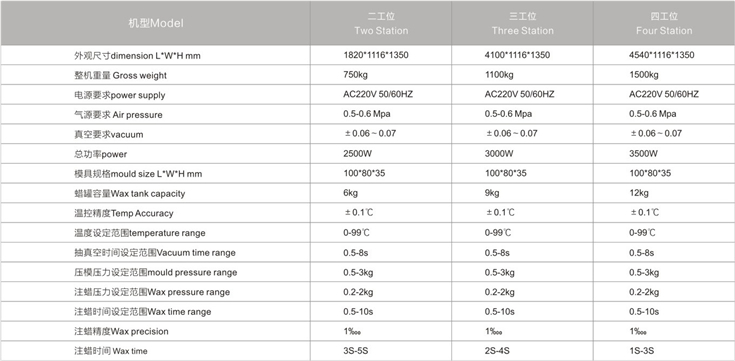

Specifications :

After sales service

Provide lifetime technical support and maintenance for the products sold. The whole machine is responsible for free warranty for any quality problems within one year. If it is not used according to the actual operating procedures, the damage caused by man-made damage and force majeure is not covered by the free warranty, only paid repairs are provided.

Dongguan Ours Industrial Co., Ltd. is committed to optimizing the jewelry process;

Buying equipment, sending technology, free training, one step in place.

Dongguan Factory Headquarters:

Songshan Lake High-tech Industrial Park, Dongguan City (24-hour service hotline: 400-9999-858)

Dongguan Exhibition Hall:

No. 11 Rongwen Road, Chang'an Town, Dongguan City (Miss Huang: 136-9185-3787)

Shenzhen Office:

Liuyue Zhonghe Shengshi District C, Longgang District, Shenzhen (Miss Li: 188-2583-5713)

Yiwu Office:

Chouzhou North Road, Yiwu City, Zhejiang Province (Miss Li: 188-0256-1183)

Technical guidance: Mr. Zeng (137-2815-5712)

Online store: www.gdours.1688.com

Email: gdours@163.com